The Windsor Essex Sewing Force

Story by Matthew St. Amand

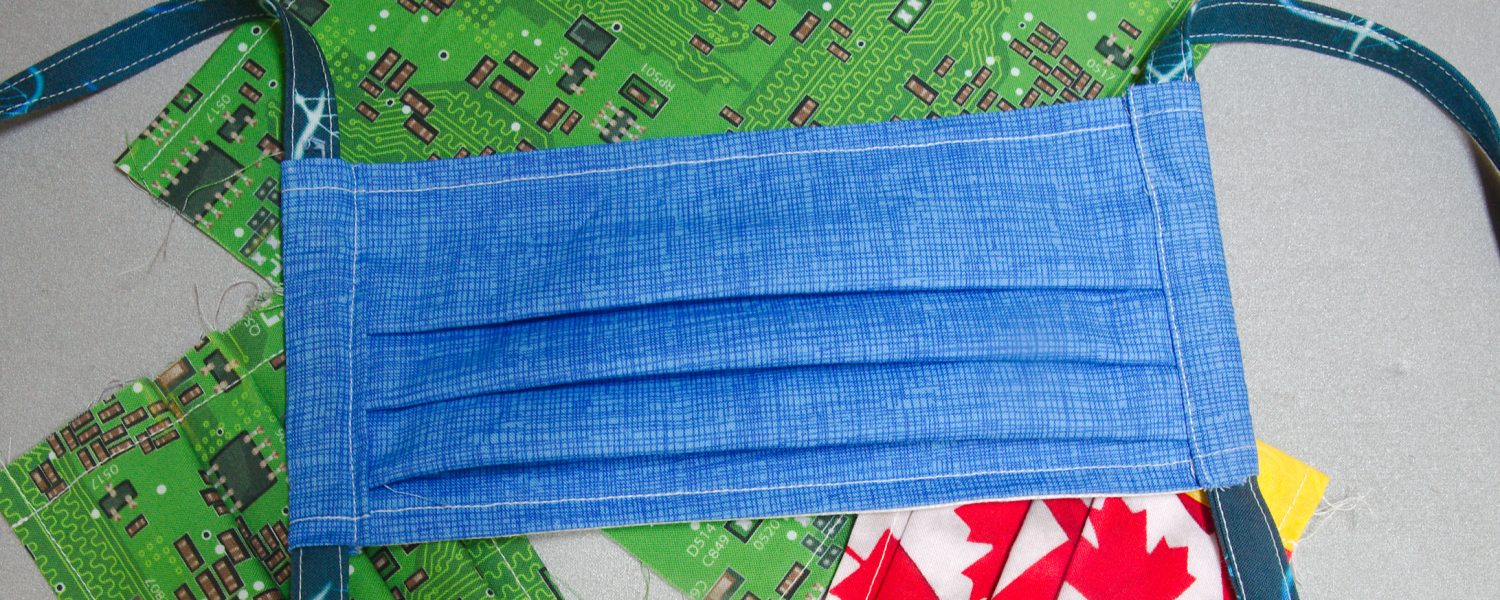

When the COVID-19 pandemic landed on the world with both feet, citizen volunteers immediately launched into action, creating homemade hospital facemasks, caps and gowns to make up the shocking shortfall of personal protective equipment (PPE) in our healthcare system: i.e. medical facemasks, caps, and gowns.

For anyone who thinks this involved a few elderly craftspeople setting aside their doilies and Queen Elizabeth commemorative needle-point, think again. The effort, which ultimately became the Windsor-Essex Sewing Force (WESF) more resembles a military operation in its scope, recruitment of personnel and logistical challenges.

Among these mask-making volunteers were Rebecca Rudman, Karen Harris (on medical leave since the summer), Kelly Mullen (left the group in mid-May), Patricia Savage, Donna Piche, Jeannie Hopkins, six Windsor-Essex women who put their sewing skills and organizational abilities to work for the community.

“We started at the end of March,” Rebecca remembers, “when Windsor Regional Hospital put out a call for homemade masks.”

Aware of the numerous, individual sewing circles in the community, Rebecca’s group organized a Zoom call with as many as they could manage.

“We knew there were a whole bunch of mask-making groups in Windsor-Essex,” she says. “We decided we could do a better job if we came together, coordinating logistics. There would be less duplication of effort.”

This was the formation of WESF. Its first order of business was research.

Rebecca’s husband, Dr. Ken Drouillard, a professor with the Great Lakes Institute for Environmental Research and School of the Environment at the University of Windsor, led the charge.

The key questions were: What was the best material for a facemask? What was the best design?

With the aid of a grant co-funded by the WE-Spark Health Institute and the Office of the Vice-President, Research and Innovation, Ken and his team tested any cotton material they could find that could be acquired locally in quantity. Testing included—but was not limited to—examining material under a GLIER Environmental Scanning Electron Microscope. Items tested included bandannas, T-shirts, tea towels, quilting cotton, high-quality quilting cotton, to name a few. Ultimately, high-quality quilting cotton was chosen because it was more dense, consistent and available.

Then to determine which pattern was best from the countless designs available online?

“A cross section of sewing volunteers formed a pattern design working group,” Rebecca explains. “We did an environmental scan of mask designs in North America and selected four to undergo a panel review by experts from two Windsor hospitals, St. Clair College, the University of Windsor, as well as local occupational experts. Important criteria were consistency, source and user protection.”

The design vetting process took about two weeks.

Two mask designs were selected. The first design WESF rolled-out was the one that was easier to sew. Both selected designs were from WESF volunteers. The chosen design was co-developed by a local surgeon and a volunteer.

“Because of Windsor’s industrial history,” Rebecca says, “we have special skills here.

Windsor has the production capability and know-how to make things and to make a lot of it. Most importantly, all the materials we use are locally sourced so we have consistent access and supporting Windsor businesses. The effort has to be sustainable.”

And then the mask-making began in earnest.

Interestingly, rolling out the formal pattern instructions and video tutorials—which involved St. Clair College’s Fashion Design department—took longer than that initial research. The WESF also developed its quality control program by the end of June which coincided with the City of Windsor allowing the volunteers to use space at the WFCU Centre as a distribution hub. Up to that point, it had all been done out of people’s homes which was slowed by social distancing protocols.

“Local quilt shops have been the unsung heroes,” Rebecca says, “working closely with WESF, doing curbside pickups. Quilting Confections, in particular, has been extremely generous with their knowledge and materials. They received a letter of recognition from the mayor’s office.”

So, who receives WESF’s masks?

The WESF website states: “We have adopted HealthEthics Alliance’s ‘Ethical Framework for the Allocation of Personal Protective Equipment (During Covid-19)’. Although it primarily applies to health care organizations and systems, which we are not, the Framework’s seven Guiding Principles of Beneficence, Equity, Reciprocity, Solidarity, Stewardship, Trust and Utility (alpha order, not order of importance). To guide us with ethical allocation to the community we are adopting the Ontario Medical Association’s Public Health Pillars for Successful Reopening to a New Normal.”

“At first, we provided masks to healthcare workers,” Rebecca says. “We have since expanded our mandate, providing masks to vulnerable groups, such as seniors and the homeless. The Windsor Health Unit distributes our masks to kids at school. In the summer, we provided masks to migrant workers.”

WESF’s Facebook group has more than 800 members and there are over 200 active volunteers.

“Our youngest volunteer is just five years old,” Rebecca says, “and our oldest is well into her nineties.” A few individual volunteers have sewn 2,000 masks, alone.

“In the early days of the pandemic,” Rebecca continues, “as healthcare providers, such as dentists and medical technicians directed all their PPE to frontline healthcare workers, our volunteers back-filled the need. At times, it became very personal and very direct. We had volunteers undergoing cancer treatment who were sewing masks for their caregivers.”

At every turn, in the early days, volunteers used their own funds to create masks. By the time WESF had received financial support from a WE-SPARK Health Institute grant, volunteers had spent $120,000 of their own money. By mid-November, WESF created upwards of 30,000 masks, scrub caps and gowns. That is one piece of PPE for every 13 people in this region.

“We didn’t even count the masks made in the first few weeks,” Rebecca says. “Many volunteers gave directly to organizations, such as Windsor Regional Hospital, so the number is definitely higher than that.”

Members of the community, such as Windsor Public Library and Valiant TMS have lent their 3D printing technology to print tools that helped WESF sew masks more easily. The Library’s contribution centered on tools to create fastening ties, which were used by volunteers when they did not have elastics. Valiant created a “puller” tool that helped pull the elastic/fabric ties through the channel of the mask. Not only did this speed mask-making, but aided elderly volunteers with limited manual dexterity.

The COVID-19 pandemic is showing few signs of abating. For all of the research, for all the community entities and local business leaders who have pitched in, the WESF’s work is not finished.

“We need donations and sewers,” Rebecca says. “Everyone has been so generous with their time and resources, but the work is not done.”

When members of local media visit the WFCU to film or photograph WESF’s efforts, they have been surprised to find there are no vast racks of shelves filled with masks.

“We don’t stockpile masks,” Rebecca says. “Masks don’t protect anyone sitting on a shelf. We make them and then we distribute them.”

The public response to WESF’s efforts has been uniformly positive.

“It’s been so well-received,” Rebecca recalls. “It’s all about people coming together. It’s not about politics, it’s neighbours helping neighbours. That’s how we do it in Windsor.”

For more information about the WESF’s work, how to help, please visit the organization’s website at www.wesf.ca.

Add comment